Image by Michał K from Pixabay

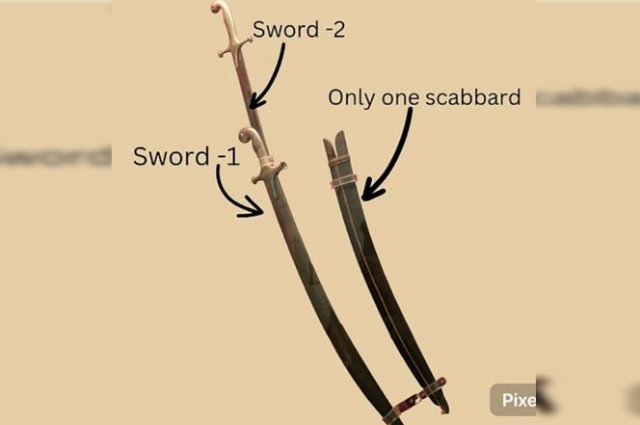

You probably have heard this proverb somewhere in your interaction with people. This is used to suggest that there cannot be two contenders for one thing. For e.g. just as there cannot be two swords in one scabbard there cannot be two kings in Kingdom. It is mostly used as a rhetoric.

Recently I had the opportunity to visit the Alwar City Museum.

The craftsmen of the princely state of Alwar proved the proverb wrong and crafted an actual “एक म्यान में दो तलवार”.

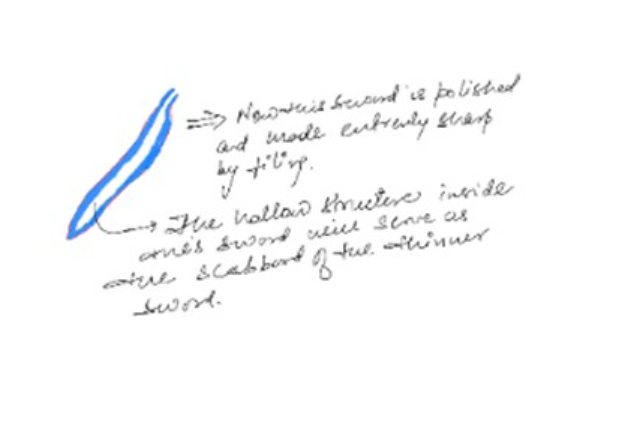

In this marvel of armament, there is a scabbard which houses a sword just like any other sword which you all might have seen in museums or movies. The interesting part is that this sword acts as the scabbard of other thinner and longer swords. Hence “एक म्यान में दो तलवार”.

Pictures of the actual sword are kept in the Alwar Museum, Rajasthan.

I could not find the actual process as to how they were crafted but I have some possible procedures which can be used to craft such a marvel of militaristic arms.

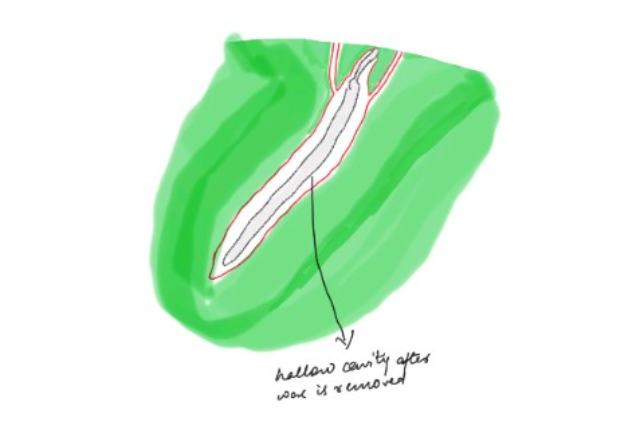

Possible explanation of the technique which might have been used to achieve this feat. The same technique might have been used in the manufacturing of the first sword i.e. the bigger one, as was used in the manufacturing of scabbards. It included two wooden sheets bound together using the adhesive technique in such a manner that a cavity is left between the two sheets which accommodates the sword.

The proposed theory is that this same technique was used for crafting the sword with a cavity inside it which could accommodate the other sword just by simply replacing the wood in the case of scabbards with metal in the case of the sword. But there are certain demerits in this theory.

The function of the scabbard doesn't demand strength & sharpness. So it is possible to craft a scabbard by simply joining two sheets and polishing over it. But this technique is not feasible for a sword as the function of the sword demands strength and sharpness of the edges.

First of all, the strength achieved by using the adhesive technique is not sufficient for a sword. Even with advanced modern adhesive techniques such as welding this is not achievable. So it is out of the question for a medieval adhesive technique to attain such strength.

Its strength is further reduced, due the filing of the edges to achieve the required sharpness of a sword. In this case, a compromise has to be made between the strength or sharpness.

In this case, there is always a looming threat of the metal sheets separating due to powerful and repeated strikes/blows of another sword or other weapon in a battle. hence not a sustainable technique of crafting swords.

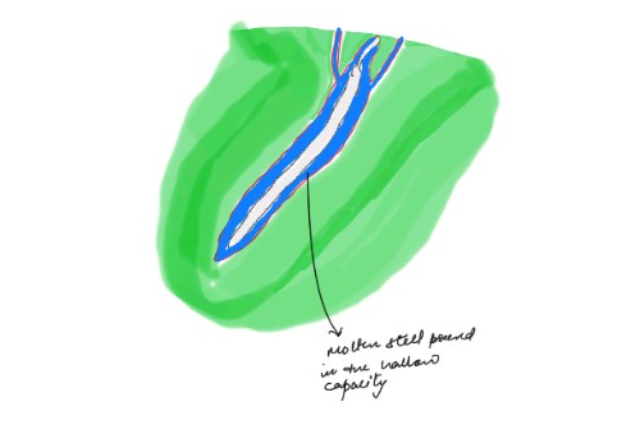

A solution for the above limitation is proposed that the sword with a hollow body is crafted by melting the edges of the two sheets together to give it the required strength for a sword.

But this solution also has its own limitations. This technique requires the metal sheets to be heated and beaten together. Beating the sheets would give the strength required but it would deform or reduce the space between the sheets that is to serve as the scabbard for the other sword. Its deformation and reduction of the available space would render it useless and prohibit it from accommodating the other sword. Thus our whole project of crafting “एक म्यान में दो तलवार” would come to an abrupt end.

A solution is also proposed to overcome this limitation. It proposes to stuff another material between the two metal sheets so that the cavity between them is not deformed or reduced. But this patch-up solution is not feasible as any other metal/material needs to be inserted deep into it, which on heating would also melt into the sheets and cannot be separated. Hence defeating our aim of crafting a sword with a cavity inside it.

If we use non-metal material like for e.g. stone to insert in the cavity. It is of brittle nature and would break into pieces, and might also turn to power in beating. Hence again not maintaining the cavity inside.

To make this technique successful it would require inserting metal with higher melting than iron for e.g. tungsten which is very rare and was discovered very recently, only in 1783. So that it would not melt on heating. Moreover, tungsten is brittle at room temperature i.e. it breaks on impact. hence cannot be used in stuffing.

My theory as to the technique that might have been used to craft “एक म्यान में दो तलवार”

LOST WAX Technique

Step 1: First a Clay form in the general shape of the sword is made.

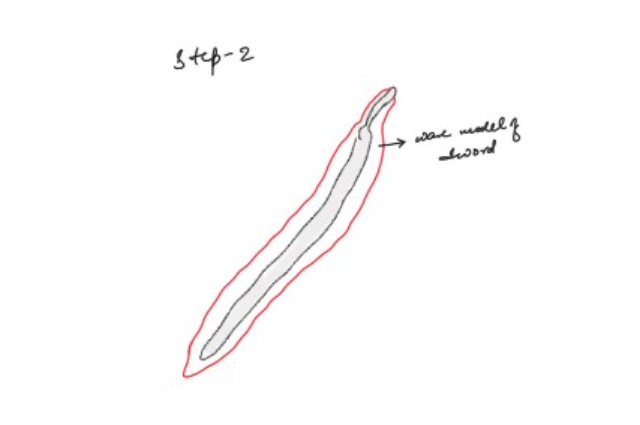

Step 2: Then the wax model of the sword is added over the clay form.

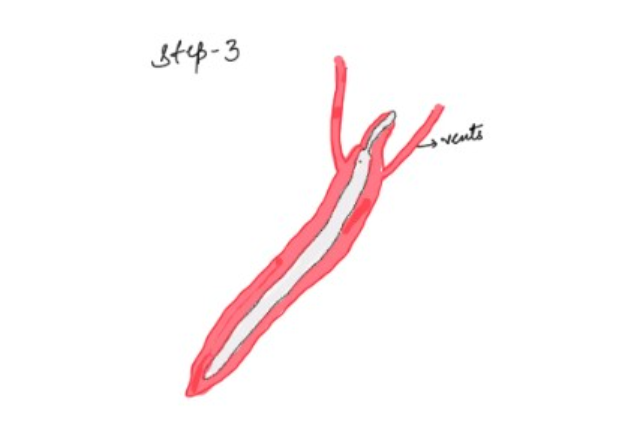

Step 3: Wax vents were added to the model, to pour metal in later steps.

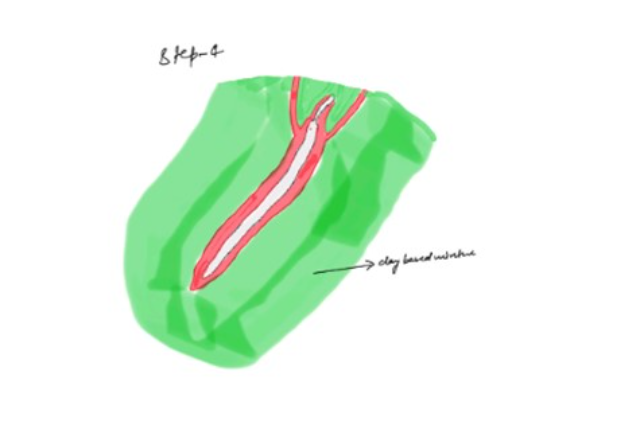

Step 4: Model is encased in a clay-based mixture which dries to form a hard mold, an opening is left for the wax to be taken out and metal poured in. (In the process the inner clay form (of step 1) is attached to the mold.)

Step 5: The mold is heated to a very high temperature to melt the wax, the molten wax is removed or lost. (Hence the name Lost Wax technique)

Step 6: The resulting void (due to the removal of wax) is shaped like the wax model due to the dried slurry, inner clay form remains attached as it is attached to the mold.

Step 7: The mold is then reheated and molten Steel/any other metal is poured into it, taking the place of the wax.

Step 8: When the Steel is cooled and solidified the outer mold and inner clay form are removed. The metal in the vents is also removed.

Now the strong monolith metal sword with a cavity inside it was ready for polishing and filing for the actual sharpness of the sword.

Now that the whole sword is a monolith of metal that is strong enough and can be filed for extreme sharpness without the fear of any adhesive to be removed.