In recent weeks, the hashtag #FundKaveriEngine has gained considerable traction across social media platforms, drawing attention to an ambitious yet often overlooked chapter in India's defense development journey. Despite its significance, the Kaveri Engine project remains unfamiliar to many, even within the country. This renewed public discourse reflects a growing interest in understanding the origins, challenges, and potential revival of India's indigenous jet engine program, a symbol of the nation’s aspiration for technological self-reliance in the aerospace sector.

The Genesis of the Kaveri Engine:

In the 1980s, India launched a strategic initiative aimed at achieving self-reliance in defense technologies. A cornerstone of this effort was the development of the Light Combat Aircraft (LCA), later named Tejas. To ensure the aircraft's complete indigenization, the Defence Research and Development Organisation (DRDO) tasked its Gas Turbine Research Establishment (GTRE) in Bengaluru with the development of an indigenous jet engine, thus marking the inception of the Kaveri Engine project. While the objective was clear, to eliminate reliance on foreign propulsion systems, the technical demands of jet engine development presented formidable challenges, particularly given the emerging state of India's aerospace infrastructure and expertise at the time.

Technical Snapshot:

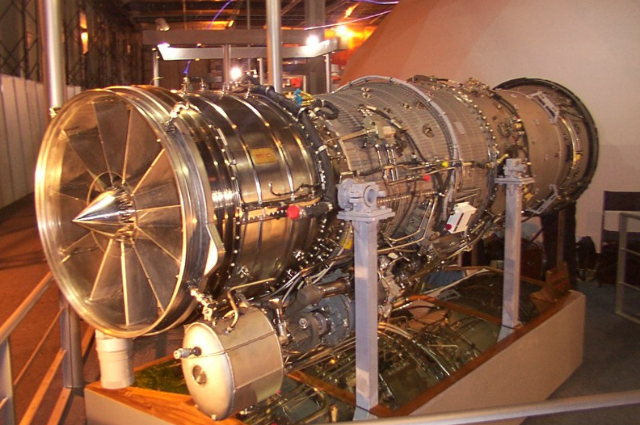

The Kaveri Engine, officially designated as GTX-35VS, is an afterburning turbofan engine. It features a low-bypass ratio, meaning most of the air drawn in is used for combustion, providing the high thrust required for fighter jets. Here’s what makes the Kaveri Engine special:

Engine Configuration

The Kaveri Engine (GTX-35VS) is a low-bypass, afterburning turbofan engine designed specifically for fighter aircraft. Its twin-spool architecture, which uses separate shafts for low and high-pressure systems, improves performance across different speeds and conditions, an essential trait for combat scenarios.

Thrust Capability

It delivers approximately 52 kN of dry thrust and up to 81 kN with afterburner, aligning it with the performance needs of light-to-medium combat aircraft. This power output places it in the same thrust class as the engines used in the current LCA Tejas and several other international fighters.

Internal Components

The engine consists of a six-stage high-pressure compressor, a three-stage fan, and single-stage high- and low-pressure turbines. These components work together to compress air, generate combustion, and convert thermal energy into mechanical power, propelling the aircraft.

Kabini Core

At the heart of the Kaveri lies the Kabini core, a compact, high-performance gas generator that forms the foundation for the engine’s thrust capabilities. It was designed for modular adaptability, potentially enabling future variants or scaled-up versions.

Intended Competitors

The engine was envisioned to match or exceed the capabilities of engines like the GE F404 (used in Tejas Mk1) and the Eurojet EJ200 (used in the Eurofighter Typhoon). This comparison sets a high benchmark in terms of performance, reliability, and efficiency. The technical foundation was solid, but the execution was another story.

Where the Kaveri Struggled:

The challenges started stacking up fast. The engine:

Overweight Design

The Kaveri engine exceeded its intended weight specifications, which negatively impacted the thrust-to-weight ratio. In fighter aircraft, excess engine weight directly reduces agility, endurance, and payload capacity. This made the engine less suitable for integration into the lightweight Tejas platform.

Insufficient Thrust Output

Despite multiple design iterations, the engine could not deliver the thrust levels needed for the Tejas to perform effectively. It remained below the 90 kN thrust class, falling short of international standards and failing to meet critical performance benchmarks during testing.

Limitations in Materials and Metallurgy

The lack of access to advanced aerospace-grade materials, such as single-crystal turbine blades and high-temperature alloys, posed a significant bottleneck. These materials are essential for maintaining engine integrity at high thermal and mechanical loads, and India’s industry was still developing these capabilities.

Recurring High-Pressure Turbine Failures

The engine experienced repeated failures in the high-pressure turbine during extended test cycles. These were caused by thermal fatigue, material degradation, and mechanical stress, leading to breakdowns during endurance runs, critical for proving airworthiness and reliability in flight.

To put it simply, we were trying to master a very advanced technology with limited infrastructure, experience, and support. International sanctions, especially post-1998 nuclear tests, didn’t help either, restricting access to crucial components and know-how.

By 2008, the Indian government officially delinked the Kaveri from the Tejas program. Instead, Tejas went with the GE F404 engine for its production models.

Why Can’t Most Countries Build Jet Engines?

It’s a valid and important question. On the surface, building a jet engine might seem like just another complex engineering task, difficult, yes, but not impossible. So why is it that only a handful of countries like the U.S., Russia, France, the U.K., and China have been able to successfully develop fighter jet engines on their own?

Developing a modern fighter jet engine is one of the most demanding engineering challenges in the world. It requires advanced materials that can endure extreme temperatures, precision manufacturing, and high-end testing infrastructure. Only a few nations possess the decades-long experience, vast supply chains, and dedicated research ecosystems necessary to master such technology.

For example, the turbine blades in a jet engine spin at over 10,000 RPM in temperatures hotter than molten lava, yet they must not melt, crack, or deform. Superalloys used in this part of the engine often require single-crystal structures and exotic coatings that only a few countries have the capability to produce or even test properly.

Finally, there’s the legacy effect. Countries like the U.S. and Russia have been refining their engine technologies since World War II. That’s nearly 80 years of accumulated research, trial-and-error, classified know-how, and evolutionary improvements. Nations like India are starting now, often while being denied access to advanced tech due to security reasons or geopolitical rivalry.

But Wait — That’s Not the End!

Even though it couldn’t power the Tejas, the Kaveri Engine wasn’t scrapped. GTRE continued work on it, and eventually, the focus shifted toward new uses:

1. Ghatak UCAV

A dry and non-afterburning version of the Kaveri is now being customized to power Ghatak, India’s autonomous stealth drone designed for long-range missions and deep penetration strikes.

2. Marine Gas Turbine Variant

DRDO has also developed a Kaveri Marine Gas Turbine (KMGT) variant to potentially power naval vessels. It’s already been tested onboard India’s marine gas turbine testbed, INS Sahyadri (retrofitted as a test ship).

3. High Altitude Testing & Foreign Collaborations

Testing in Russia is ongoing, with only around 25 hours of trials left. Once completed, it will cross the 100-hour test mark, a major milestone. Simultaneously, there have been discussions for technical collaboration with international engine giants like Safran (France) and Rolls-Royce (UK) for Kaveri’s evolution and integration into future fighter platforms.

Fueling the Future, One Tweet at a Time:

In April 2025, the hashtag #FundKaveriEngine began trending across Indian social media platforms, sparked by defense enthusiasts, aviation followers, and concerned citizens. What began as a niche conversation quickly transformed into a national movement. The demand was clear: revive the Kaveri Engine program with renewed financial backing, modern engineering expertise, and political will.

What sets this campaign apart is how ordinary citizens are now leveraging social media as a strategic tool, not just for awareness but as a means to shape defense discourse. In a country where access to high-level defense discussions is typically limited to policymakers and experts, this movement marked a shift, people were no longer just spectators of strategic development, but vocal participants.

Calls for transparency and renewed funding drew parallels with India’s space journey. Many online voices cited how ISRO overcame initial setbacks with its cryogenic engine through persistence and government support, arguing that DRDO, with lessons learned and India’s improved technological base, could do the same for Kaveri. Veteran pilots, ex-IAF officials, and even aerospace engineers publicly lent their support, emphasizing that a truly self-reliant air force must also be free from foreign engine dependency.

Public pressure, when informed and sustained, can serve as a powerful motivator for political reflection. It forces institutions to revisit stalled or sidelined programs, re-evaluate priorities, and respond with a clearer sense of accountability. In a democracy, strategic decisions, especially those involving taxpayer funding and national defense, must reflect not only top-down directives but also bottom-up public will. Movements like #FundKaveriEngine don’t just seek revival of a project; they demand transparency in progress, accountability in investment, and faith in national capability.

This resurgence of public interest may well become a defining factor in how India re-engages with its indigenous jet engine dream.

Why Jet Engine Autonomy Matters for National Security?

The development of indigenous jet engine technology is a cornerstone of strategic and technological sovereignty for any nation. For India, achieving self-reliance in this domain is not just a milestone in defense capability but a critical step toward reducing dependency on foreign suppliers. Jet engines are among the most tightly controlled and export-restricted components in the global defense supply chain. Owning this capability ensures operational continuity of air assets, even in the face of shifting geopolitical alliances, sanctions, or export denials.

Moreover, indigenous propulsion systems elevate the credibility and competitiveness of India’s defense exports. A fully homegrown fighter aircraft, including its engine, significantly enhances the appeal for international buyers by eliminating licensing issues and third-party dependencies. It allows India to offer turnkey solutions and to engage more deeply in defense diplomacy.

From a broader perspective, the successful design and production of a modern military jet engine is a recognized indicator of high-end technological maturity. It demonstrates proficiency not only in advanced engineering and material science but also in long-term innovation ecosystems. Very few nations possess this capability, and joining that elite group signals a new level of industrial and strategic sophistication.

In essence, indigenous engine development is not just about self-sufficiency—it is about securing a resilient, future-ready defense infrastructure that aligns with national security priorities and economic aspirations.

India’s Engine of Independence:

In the end, the story of the Kaveri Engine is not one of failure, but of persistence, a testament to India’s unwavering resolve to achieve technological sovereignty in the face of adversity. While setbacks have marked its journey, they have also laid the groundwork for a more resilient and capable future. Today, with advanced materials, mature expertise, and a generation of engineers who dream bigger, India is better positioned than ever to complete what it started.

Reviving the Kaveri project is more than a technical challenge, it is a national calling. It liberates us from external pressure, strengthens our export potential, and signals to the world that India is ready to lead not just in ambition, but in execution.

As citizens rally behind this cause and as institutions take notice, the path forward is clearer. The dream of an indigenous jet engine is no longer just an aspiration, it is an achievable reality. With unity, vision, and determination, India can ignite the Kaveri once more and let it roar not only through our skies but through the annals of global aerospace history.