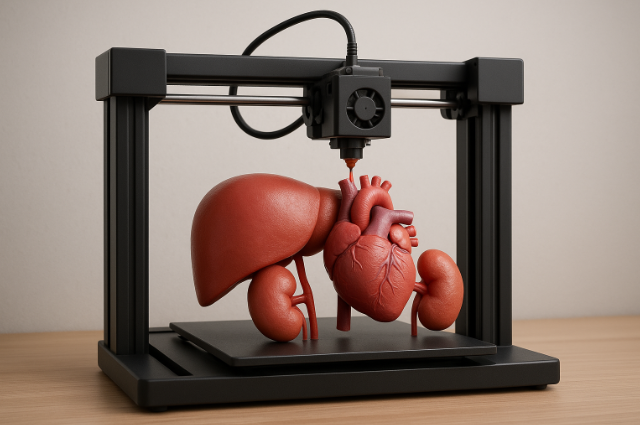

For decades, one of the greatest challenges in modern medicine has been the shortage of donor organs. Thousands of patients around the world remain on waiting lists for kidney, liver, or heart transplants, and many never receive the life-saving surgery they need. This crisis has inspired researchers, doctors, and engineers to seek alternative solutions. One of the most exciting innovations is the possibility of 3D-printed organs—living tissues created layer by layer through specialized bioprinters.

This breakthrough combines engineering, medicine, and biology to create hope for a future where no patient must die waiting for a donor. At its core, 3D bioprinting works similarly to traditional 3D printing. Instead of using plastic or metal, bioprinters use “bio-ink,” a mixture of living cells and biomaterials. Engineers program the printer to lay these materials in precise layers, forming complex structures that mimic natural tissues. Under the right conditions, the cells grow, interact, and gradually function like living organs.

Research and Techniques

Many early breakthroughs have already demonstrated the power of bioprinting.

In 2019, researchers in Israel successfully printed a small but functional heart using a patient’s own cells. Although it was only rabbit-sized and not ready for human use, it proved that vascularized organs could be created in a lab.

At the Wake Forest Institute for Regenerative Medicine in the U.S., scientists printed small human tissue samples that were later transplanted into animals, where they continued functioning.

In Sweden, researchers created a 3D-printed cartilage transplant for patients with nasal injuries, showing how printed tissue can directly improve lives.

These early examples highlight what the future might look like—customized, lab-grown organs tailored to individual patients.

Industry Applications and Potential

For governments, hospitals, and corporations, 3D-printed organs hold enormous appeal.

- Addressing Donor Shortages: By eliminating reliance on human donors, bioprinting could drastically reduce waiting lists and deaths caused by organ failure.

- Medical Testing: Pharmaceutical companies can use 3D-printed tissues to test drugs more accurately, reducing the need for animal testing.

- On-Demand Healthcare: Hospitals may one day establish in-house bioprinting labs to build customized tissues for patients.

- Commercial Opportunities: Biotechnology firms view bioprinting as both life-saving and a strategic investment in the rapidly growing regenerative medicine market.

Beyond organ replacement, bioprinting has the potential to transform other fields of healthcare:

- Burn victims could receive 3D-printed skin that perfectly matches their own.

- Athletes with cartilage damage could recover faster through custom tissue transplants.

- Cosmetic surgery could use bioprinted tissues for natural-looking results.

- Importantly, bioengineered organs could also reduce the global black-market trade in human organs by providing safe, regulated alternatives.

Challenges Ahead

Despite its promise, several challenges remain:

- Complexity: Human organs are intricate networks of blood vessels, cells, and tissues. Printing a viable organ that functions long-term in the human body remains extremely difficult.

- Cost: Bioprinting technology is still very expensive and requires heavy investment for scaling.

- Regulation: Governments must ensure that 3D-printed organs are safe, ethical, and effective before approving them for hospitals.

Still, progress continues. Engineers are developing better bio-inks, more advanced printers, and smarter designs that more closely replicate natural tissue. Experts predict that within the next two decades, bioprinted tissues such as skin and cartilage will be widely available, while more complex organs like kidneys and hearts may follow within our lifetime.

3D-printed organs may not yet be ready for mainstream hospitals, but they represent one of the most revolutionary frontiers in engineering and medicine. Early examples—such as the printed heart in Israel and cartilage transplants in Sweden—prove the technology is possible. The road ahead will require investment, innovation, and collaboration, but the potential is life-changing.

One day, when a patient is told they need a transplant, they may no longer have to wait for a donor. Instead, their new organ could be designed, printed, and transplanted—a remarkable gift of life made possible through engineering.