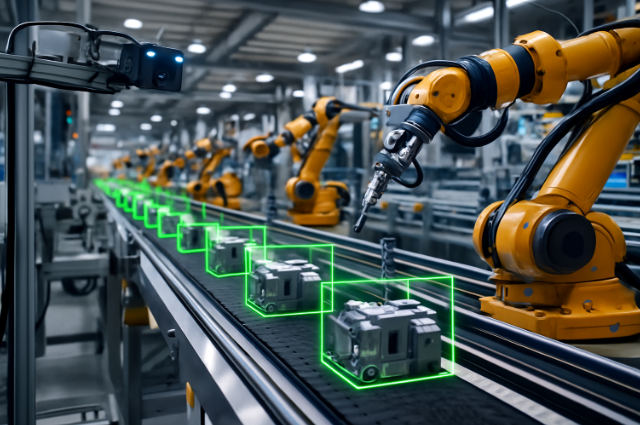

There have been no stories to tell in the factories; you can literally hear them in the whirr of machinery, the tramping of employees, the bang of metals, and the beat that gives a production line its life. However, nowadays, it has heard another narrator who has no face, no voice, but can see all. The Computer Vision AI is emerging as a silent narrator of the factory floor, deciphering thousands of visual cues into information on quality, efficiency, and risk. Manufacturing is not only becoming automated in this shift but making intelligent awareness.

In the center of all manufacturing, one will find a ballet between machines and humans. The experience and instinct are relied on by workers, and the machine would provide them with speed and precision. Nevertheless, both parties have their boundaries. The eyes of people are tired; machines cannot do anything but crash. Even a small fault, a microscopic crack, a minor malalignment, or a slight modification of color, may go undetected and be passed along the line, and eventually lead to an expensive recall or even a safety risk. Here, the new storyteller comes in, Computer Vision AI never becomes tired or misses anything. It tracks all production stages, takes photos and video feeds, processes them in real time, and explains what is going on on the factory floor. It does not merely indicate what has gone wrong, but it shows what has worked out, what did not work out, and what may go wrong in case nothing is done.

A good case study of this transformation is done by a leading Indian automaker, which faced a single problem that kept on recurring; the reason was that defects in the engine parts were being detected very late in the production process. Employees were experienced and competent, yet some of the imperfections were too minute to be spotted by human senses, such as hairline fractures, minute flaws in alignment, or minor differences in component design. The company was spending money and time on these defects. The car manufacturer responded to this by implementing a Computer Vision AI model in its engine assembly line. Thousands of images with ideal and faulty parts were used to train the AI, creating a vast visual vocabulary that enabled the detection of typical patterns and hazardous anomalies. The storytelling effect of this experiment was what made it stand out from the crowd, what AI transformed bare visuals into a moving production narrative.

The AI scanned engine components a high speed daily and alerted on the problems that no employee can have possibly detected. It did not just stop at identifying defects but it started to predict them as well. It identified indicators of equipments being worn out, identified abnormal vibration patterns using slight visual indicators, and signaled probable equipment breakdowns that occurred earlier than normal. It turned out that the automaker was creating a plot: the AI was not only analysing images, but also creating a narrative. It would say, “This machine is straining, or this part is a little out of position compared to yesterday, or this little blemish will cause a huge problem by Step 12. This technology led to a decrease in the number of defect-related downtime by 25 percent and an increment in overall effectiveness by a margin of more than 18 percent in less than six months.

Historically, quality control in the factories is based on human judgment and post-production inspections. However, it is now a conversation between technology and the production line

through Computer Vision AI, which ensures quality assurance. The employees are now getting numbers of alert messages in the real time: This component is not up to the standard or Stop and re-read this step. Teams are now able to respond immediately instead of discovering the faults once the process is completed and prevent the errors to expand. This has even resulted in the increase of the status of the workers. No longer do they need to spend hours visually inspected in order to see the items, but they work as supervisors to the AI, interpret the alerts, make decisions and enhance processes. Its experience is even more beneficial since the AI gives the clearness of evidence of all the problems it identifies.

Such a fact that the Computer Vision AI reinforces and does not substitute human judgment is one of the most captivating. AI will identify patterns and flaws, but human beings makes sense. They can tell when a machine is not functioning as it should due to the humidity or when something is not going well with a part even though the camera may be telling them that all is well. Humans and AI are depicted as one huge perspective of narration which reinforces the structure of the factory. It is narrated by the AI what it can observe; human beings explain the meaning. It is efficiency that comes with a combination of both viewpoints.

In the future, the actual strength of Computer Vision AI is prediction. Already, cameras and sensors are able to detect visual indicators that reflect indirectly on the body showing signs of equipment burnout, a slightly out of place bolt, a slight temperature change, a slight wobble in the vibration. In the nearest future, factories are going to work as intelligent systems in which all components would communicate visually with the help of AI. Technology will be in a position to say, this is what will happen tomorrow unless you act on it now. It will enable the production managers to plan efficiency in advance avoiding downtime and instead responding to it.

Manufacturing has always been a numeric speaker: the cycle time, output rate, percentages, but there is a new language forming: the visual language of AI. Each frame that is shot tells a little portion of the big story. It can display a machine that is operating better than it was yesterday, a conveyor belt that is moving with excessive smoothness, a part that does not fit the pattern, or a stage where quality starts to be compromised. These frames combined provide factories with some kind of narrative consciousness they had never possessed previously. The Computer Vision AI becomes more of a tool and even a narrator with the ability to transform how factories perceive efficiency, quality, and safety.

This is a turning point into the success of the Indian automaker. Interesting in that it lets AI monitor and report on its manufacturing assembly line, the company was able to establish a more intelligent, safer, and efficient factory space. Here is the new age of production one in which plants no longer operate; they read themselves. One where misfortunes do not stand out like the proverbial sore thumb. One in which production is a day-to-day, visual narrative which is getting better every day. Computer Vision AI is the most responsive narrator that the factory floor has ever experienced in this new world.

References

- Beltrán, J., Molina, J., & García, J. (2024). A review of how computer vision enhances defect detection and quality control in automotive manufacturing.

- IMARC Group. (2024). Report on the growing use of AI-driven quality inspection systems in Indian manufacturing.

- Visionify.AI. (2023). Overview of computer vision applications for real-time inspection, defect spotting, and process monitoring.

- Third Eye AI. (2023). Case study detailing how AI identifies micro-defects in automotive parts more accurately than manual inspection.

- Eightgen AI. (2023). Case study demonstrating improved factory efficiency and near-perfect accuracy through AI-powered quality checks.GeeksforGeeks. (2023). Explanation of practical computer vision use cases in modern manufacturing environments.